©2024 FAN SEPARATOR GmbH

Well stirred liquid manure guarantees even distribution of nutrients and a homogeneous consistency. This makes the further processing simpler and more efficient. Optimal homogenisation can be relied upon with the MSXH series from FAN. The FAN stirrers are outfitted exclusively with high-efficiency motors and planetary gears with an overall efficiency on the order of 90%, which often permits the use of a unit one full category lower. The choice between fast or slow stirrers is a matter for debate – but both types can be purchased from FAN.

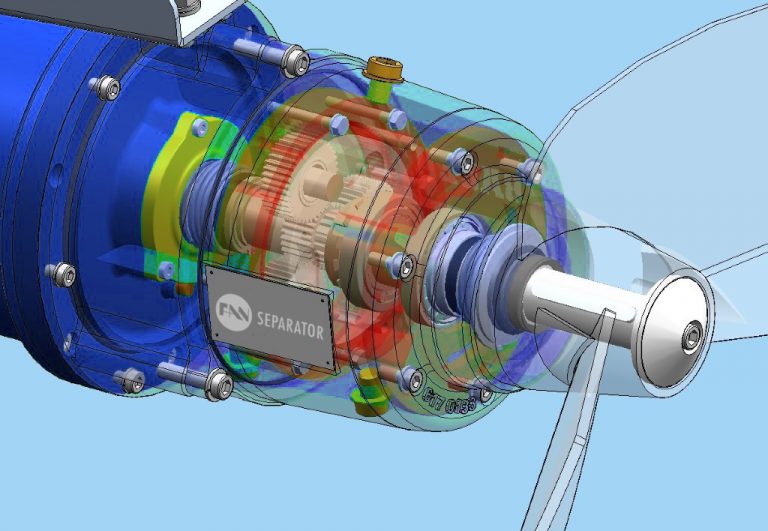

A special concept that puts the motor and propeller shaft in the same axial plane ensures a high level of efficiency.

The resulting slim and streamlined shape further improves the efficiency. The propeller shaft is robustly dimensioned and fitted with angular roller bearings.

An ingenious oil distribution system ensures optimal lubrication of the submersible motor stirrer at any angle of inclination.

Leak sensors are also standard on the MSXH models.

Thanks to the planetary gear, the stirrers have an elegantly streamlined shape. Together with the large stirrer blade and the special stirring edge, this makes for high efficiency.

| MSXH | MSXH 5.5 | MSXH 7.5 | MSXH 8.6 | MSXH 11 | MSXH 11 ECO | MSXH 12.6 | MSXH 15 |

|---|---|---|---|---|---|---|---|

| Output kW | 5,5 | 7,5 | 8,6 | 11 | 11 | 12,6 | 15 |

| Voltage V | 400 | 400 | 240/480 | 400 | 400 | 240/480 | 400 |

| Frequency Hz | 50 | 50 | 60 | 50 | 50 | 60 | 50 |

| Stirring power* m³/h | 2.800 | 3.600 | 3.900 | 5.200 | 5.700 | 5.700 | 6.800 |

| Pit volume* m³ | 900 | 1.400 | 1.500 | 2.200 | 2.400 | 2.400 | 2.800 |

| Propeller min-1 | 315 | 315 | 378 | 315 | 208 | 378 | 315 |

| Weight kg | 175 | 195 | 195 | 205 | 205 | 205 | 225 |

Lifting and lowering mechanism for open and closed containers

Usable in deep canal systems

Optional: Height-adjustable stirring tunnel with retaining tarpaulin to ensure optimal stirring.

Slalom system

Automatic homogenisation of the slurry in the endless canal via timer control

Guide bracket with adjustable inclination

This results in better stirring performance and faster elimination of floating and sinking layers.

Lifting and lowering mechanism with gas-tight wall pass-through