©2024 FAN SEPARATOR GmbH

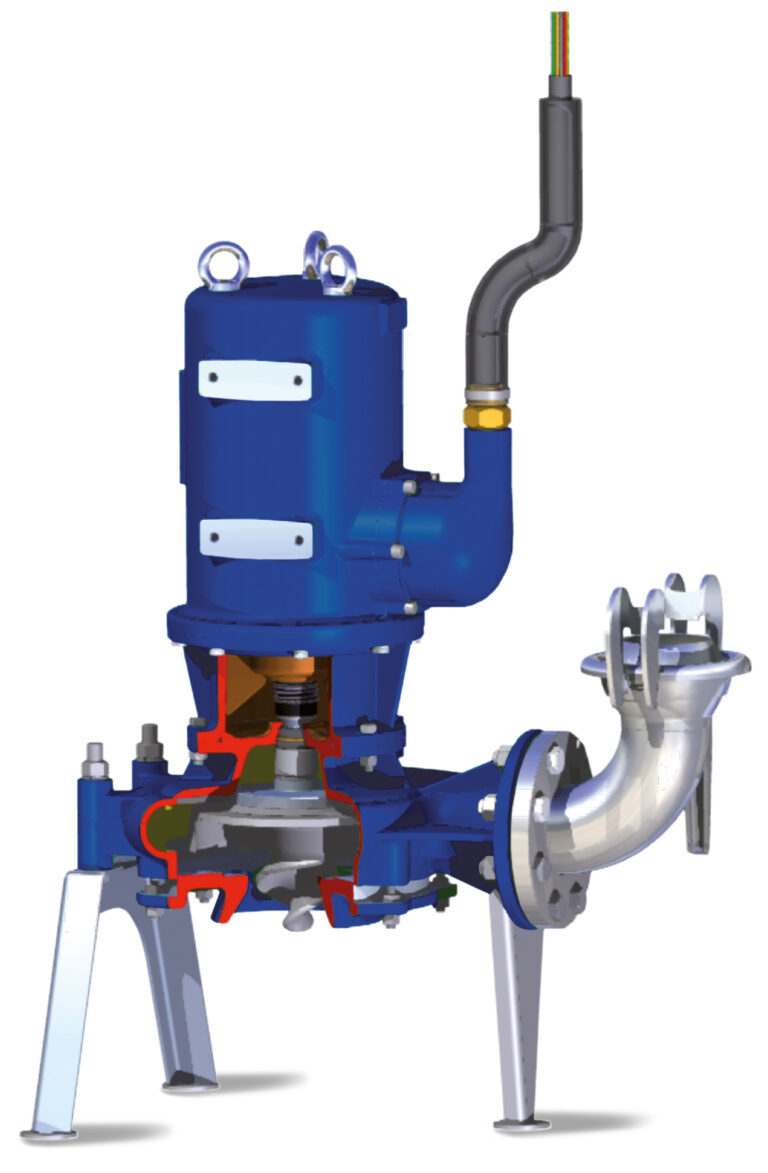

The FAN submersible motor pump series ESPH/CSPH impresses with its tremendous output and long service life. The pumps operate below the surface of the liquid manure or waste water and can be used in diverse applications.

The main difference between the two designs, CSPH and ESPH, is the cutting unit:

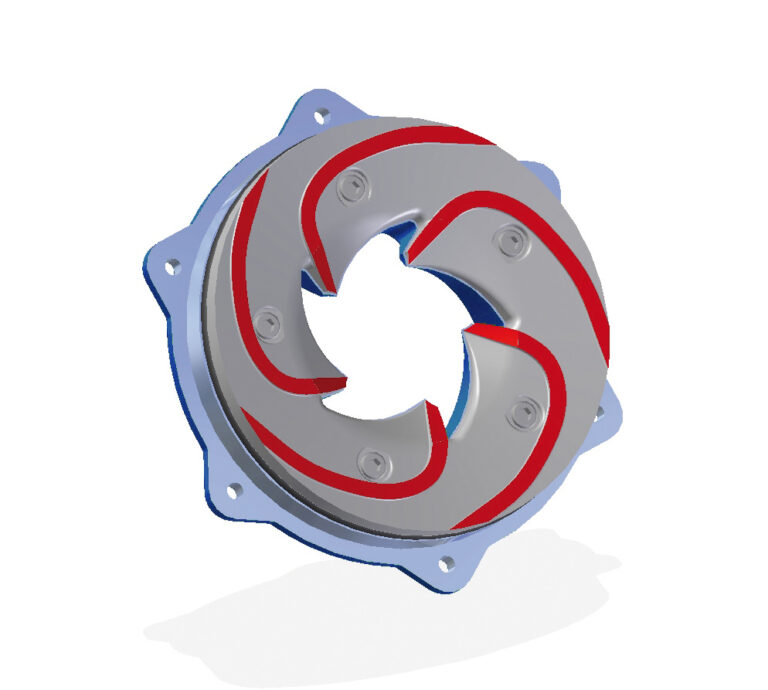

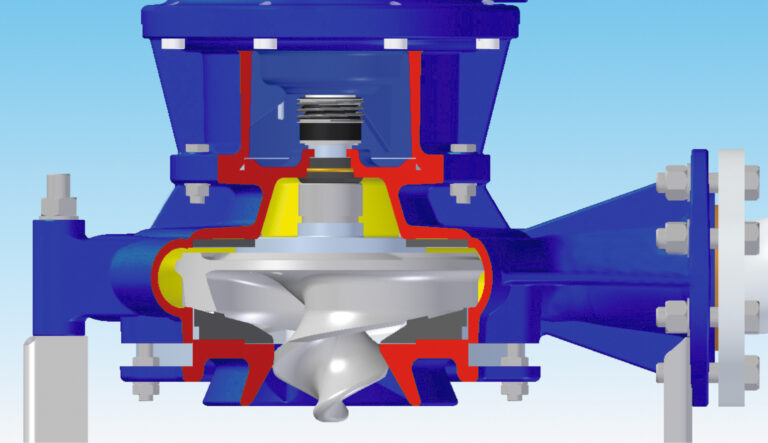

The CSPH (Cutting Submersible Pump) is equipped with an adjustable cutting unit, impeller and cutting disc of chromium steel.

The ESPH (Effluent Submersible Pump) does not have a cutting unit, and its impeller is made of spheroidal graphite iron.

The FAN submersible motor pumps offer outstanding performance figures: Up to 80 m³ of liquid per hour can be pumped by the CSPH/ESPH at an impeller speed of 1,450 rpm. The pump head is 13 m.

FAN submersible motor pumps offer impressive performance figures: Up to 80 m³ of liquid per hour can be pumped by the CSPH/ESPH at an impeller speed of 1,450 rpm. The pump head is 13 m. This makes the pump a perfect match for FAN products such as the Bedding Recovery Unit or the compact separator PSS 1.1-300.

Naturally, the pump is ideal for typical manure management as well.

The CSPH/ESPH is perfect for:

One major advantage of the CSPH is its high-performance, adjustable and replaceable cutting unit made of premium chromium steel. This results in impressive cutting performance and a long pump lifespan. The wear plate in the spiral housing is replaceable as well.

Thanks to a specially designed impeller and suction bell geometry, excellent efficiency can be achieved over a wide operating range. This clearly differentiates the FAN ESPH/CSPH series from other products on the market.

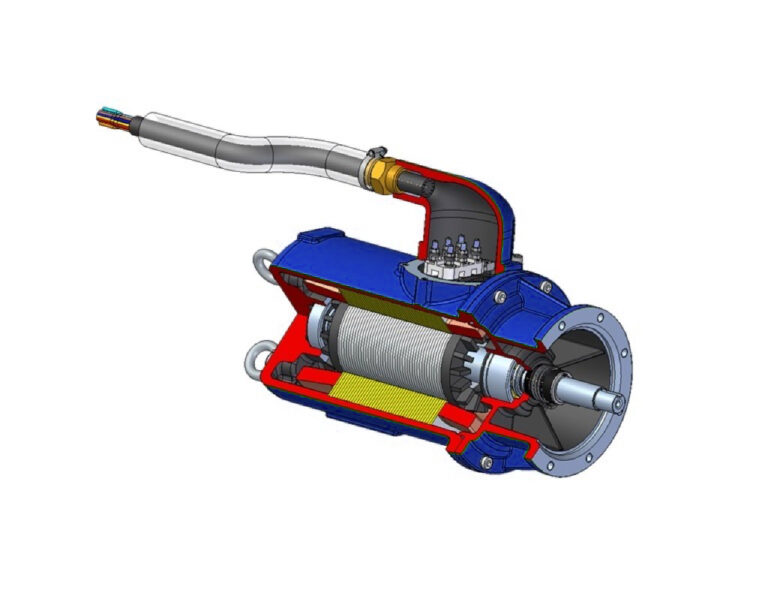

The Magnum submersible motor pumps are driven by a three-phase submersible motor with an output of 4.0 to 15 kW. The unit has an efficiency of 88.3%, putting it in efficiency class 1. The motor also boasts insulation class H and can be optionally fitted with temperature monitoring. Thanks to these features, the ESPH/CSPH pumps can also be used in biogas systems without restrictions. A special leak sensor in the motor provides additional operational safety.

| Model | Flow rate m³/h | Manometric height m | Max. drive power kW | Max. Ampere A | Drive speed min-1 | Delivery connection mm |

|---|---|---|---|---|---|---|

| ESPH 4 | 20-100 | 13,0-7,0 | 4,0 | 8,1 | 1.450 | DN 80 |

| ESPH 5,5 | 20-120 | 20,0-9,8 | 5,5 | 10,7 | 1.450 | DN 80 |

| ESPH 7,5 | 20-200 | 19,6-5,5 | 7,5 | 15,6 | 1.450 | DN 100 |

| ESPH 11 | 20-240 | 22,3-8,2 | 11 | 22,0 | 1.450 | DN 100 |

| ESPH 15 | 20-250 | 24,0-9,1 | 15 | 28,6 | 1.450 | DN 100 |

| Model | Flow rate m³/h | Pump head m | Max. drive power kW | Max. Ampere A | Drive speed min-1 | Delivery connection mm |

|---|---|---|---|---|---|---|

| CSPH 4 | 20-100 | 12,3-5,9 | 4,0 | 8,1 | 1.450 | DN 80 |

| CSPH 5,5 | 20-120 | 19,2-8,2 | 5,5 | 10,7 | 1.450 | DN 80 |

| CSPH 7,5* | 20-120 | 19,2-8,2 | 7,5 | 14,9 | 1.445 | DN 80 |

| CSPH 7,5 | 20-180 | 19,5-5,1 | 7,5 | 15,6 | 1.450 | DN 100 |

| CSPH 11 | 20-230 | 22,0-6,9 | 11,0 | 22,0 | 1.450 | DN 100 |

| CSPH 15 | 20-240 | 23,7-7,4 | 15,0 | 28,6 | 1.445 | DN 100 |