©2024 FAN SEPARATOR GmbH

The German agricultural cooperative Agrargenossenschaft Reichenbach produces bedding with the BRU 2000. After five years, it is clear that the results are extremely positive. And the cows are very satisfied as well.

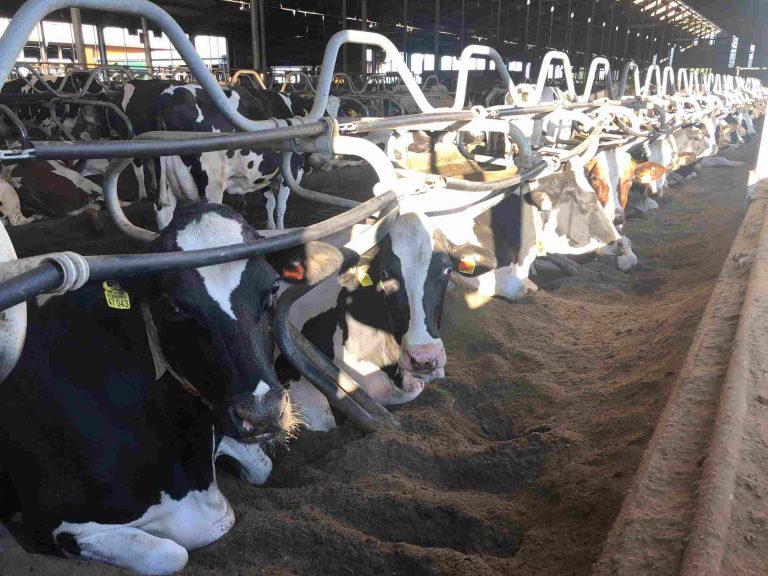

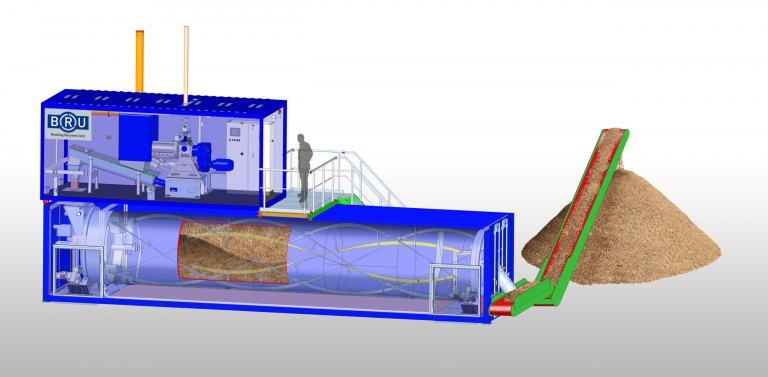

Creating hygienically safe bedding from slurry: made possible thanks to the BRU (Bedding Recovery Unit). In Europe an increasing number of farms are making use of this sustainable system from Bauer and FAN. One of these is the agricultural cooperative Agrargenossenschaft Reichenbach eG in the Vogtland region of Saxony, whose general manager Lars Bittermann is very satisfied with all aspects of the innovative slurry processing system. Bittermann is especially impressed by the soft, extremely absorbent bedding. He describes the material as “more comfortable and better than sand,” and the animals on his farm have accepted it very well.

The German farm, which encompasses 1,800 ha of agriculturally usable land and manages a diary operation with 1,000 cows, has been using the BRU 2000 since 2017. Every day, 25 m3 of material is processed, which amounts to one third of the farm's slurry output. The agricultural cooperative, with its 54 employees, stores the separated bedding in a purpose-built bunker. Five to seven tons of material are produced and then distributed in the stalls every two days after mixing with lime.

Previously, Bittermann always had problems with the old bedding system used on his farm due to the high levels of bacteria. Salmonella was able to spread unhindered. Nevertheless, Bittermann wanted to continue with the practice itself and eventually heard about the processing system from Bauer for separating and sterilizing slurry. This system enables the production of hygienically safe bedding from recycled material – exactly what Bittermann was looking for. The BRU proved to be exactly the right choice. The veterinary inspection office that carries out regular monitoring has also given the tested bedding material top marks.

Another very positive aspect appreciated by Bittermann is the ease of maintenance. The daily system inspection takes only five to ten minutes. Once per week, all the nipples are lubricated, which takes just half an hour. For this farm manager from Saxony, it was the right purchase at the right time.

Call us:

+499227938400

E-Mail us:

info@fan-separator.de

https://www.facebook.com/fanseparator