©2024 FAN SEPARATOR GmbH

Massive amounts of diverse wastes are produced daily in slaughterhouses, posing a significant challenge to all such operations. Separators play a critical role in disposal management and assist slaughterhouses in complying with environmental regulations, which are particularly strict in the meat processing industry. With efficient solid/liquid separation, waste water can be reused and waste volumes reduced, saving on expenses for transport and disposal. Separated slaughterhouse wastes can also be processed into compost, spread as fertiliser or used for the production of biogas.

FAN offers a full product range for solid/liquid separation and the dewatering of solids at slaughterhouses of all sizes. Depending on the material in question, the disposal costs can be reduced by up to 75%.

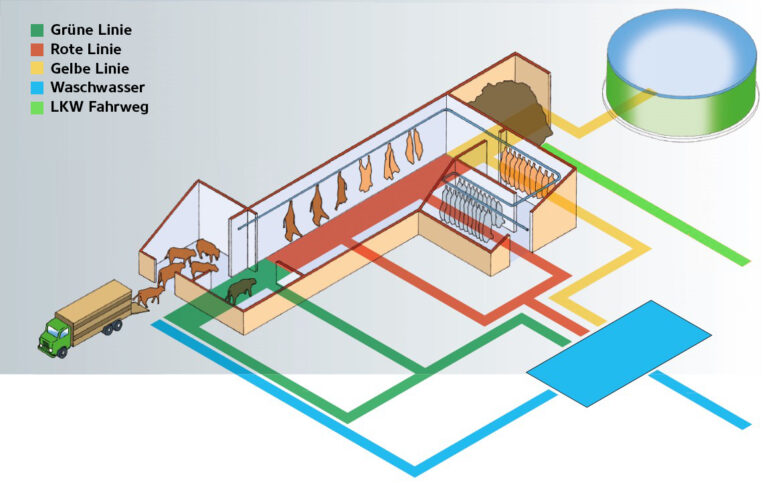

In the industry, the waste water from slaughterhouses is divided into various streams, called green, red and yellow lines.

The green line includes waste water arising in the course of deliveries to the slaughterhouse, such as water from washing the trucks that deliver the animals. The separated solid consists largely of plant matter and can be composted, for example. The dewatering of rumen contents also falls within the green line. The red line consists of all the waste water arising in the slaughterhouse itself. The yellow line is made up of the stomach and intestine contents, which can be reduced significantly in volume via solid/liquid separation. The requirements on the separation technology differ for each of these three lines.

The green line comprises waste water arising in the holding pen or from cleaning of the animal transport trucks and refrigerated trucks. The separated solid phase consists largely of plant matter and can be composted or spread as fertiliser.

The cleaning of the trucks introduces straw, wood shavings or manure into the waste water. Separation ensures that these solids do not enter into the sewer network. The separated liquid phase can be fed into the in-house or municipal water treatment plant, for example. The volume and weight of the solids are significantly reduced by the dewatering, which also lowers the disposal costs. However, many slaughterhouses use the solid phase as compost or fertiliser or feed it into their own or an external biogas system.

The dewatering of rumens, which contain vegetable matter, is also assigned to the green line. During the slaughtering of cattle, each animal yields a not insignificant quantity of rumen contents, which consist largely of water. Separation reduces the volume and weight of the rumen, making disposal simpler and cheaper.

The red line consists of all the waste water arising in the slaughterhouse itself. For example, this includes blood as well as bristles and hooves. The waste water from the rumen separation is also sent to the red line.

The yellow line is made up of the stomach and intestine contents. Separation significantly reduces the mass of this unusable material, which must be disposed of. This can result in up to 75% lower disposal costs.

It is becoming increasingly popular to feed separated waste from slaughterhouses into biogas systems. This allows the waste to be used effectively to generate energy and heat. Here are some examples of real-world applications:

These two PSS 3.2-780 separators are used for treating slaughterhouse waste water from the slaughtering of cattle in northern Germany. The solid phase is disposed of. The thin phase is first fed into a sand separator and then a flotation system. It is then treated further by the addition of auxiliary materials. The flotation sludge is fed into a biogas system to generate heat and energy. The waste water goes to a treatment plant.

This separator PSS 5-520 has also been working in a slaughterhouse for many years: It is used to separate washing water from in-house stables and animal transport trucks. The separated solid is fed into biogas plants to generate energy. The liquid phase is fed to the sewage treatment plant.

Call us:

+499227938400

E-Mail us:

info@fan-separator.de

https://www.facebook.com/fanseparator